Condition:

New

No. Of Spindles:

Single

Type:

VERTICAL

Weight (T):

6.1 T

Table Size (mm):

1200 X 600

CNC Control System:

GSK, FANUC, MITSUBISHI, KND, Siemens

Number Of Axes:

3, 4

Table Travel (X) (mm):

1100

Table Travel (Y) (mm):

600

Table Travel (Z) (mm):

600

Positioning Accuracy (mm):

±0.005

Repeatability (X/Y/Z) (mm):

±0.003

Spindle Motor Power(kW):

11

Max. Table Load(kg):

800 Kg

Feed Speed(mm/min):

1 - 10000 Mm/min

Rapid Feed Speed(m/min):

36/36/36

Min. Time Of Tool Change(s):

3

Tool Magazine Capacity:

24

Key Selling Points:

Multifunctional

Warranty:

1 Year

Voltage:

As Your Requirements

Applicable Industries:

Machinery Repair Shops, Manufacturing Plant

Showroom Location:

Egypt, Turkey, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan,

Marketing Type:

NEW Product

Machinery Test Report:

Provided

Video Outgoing-inspection:

Provided

Warranty Of Core Components:

1 Year

Core Components:

Motor

Three-axis Travel (X/Y/Z):

1100/600/600mm

Worktable Size (L X W):

1200x600mm

Max. Loading:

800

Spindle Speed:

8000rpm

Spindle Taper:

BT40

Spindle Motor Power:

11KW

Fast Moving Speed (X/Y/Z Axis):

36/36/36m/min

Cutting Feed Rate:

1-10000mm

Number Of Tools:

24

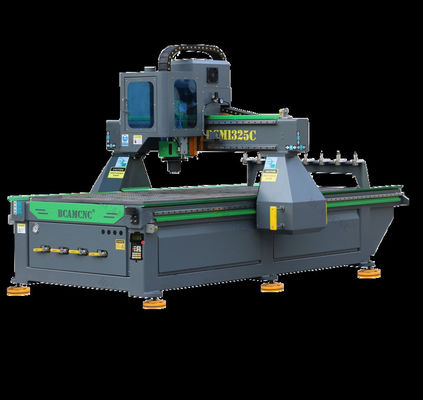

Product Name:

VMC1160 DISK Type ATC Low Price VMC Vertical Machining Center

After-sales Service Provided:

Online Support, Video Technical Support, Field Installation, Commissioning And Training, Field Maintenance And Repair Service

After Warranty Service:

Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Local Service Location:

Egypt, Turkey, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Malaysia, Australia, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South

Certification:

CE

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!