Condition:

New

Type:

TURNING CENTER

Year:

2022

Max. Length Of Workpiece (mm):

600mm

Max. Spindle Speed (r.p.m):

8000 R.p.m

Machining Capacity:

Medium Duty

Max. Weight Of Workpiece(kg):

800

Spindle Bore(mm):

150

Width Of Bed (mm):

80 Mm

Spindle Motor Power(kW):

11/15

No. Of Spindles:

Single

Max. Turned Length (mm):

1100

Number Of Axes:

3

Travel (X Axis)(mm):

1100 Mm

Travel (Z Axis)(mm):

600 Mm

Positioning Accuracy (mm):

±0.003/3000

Repeatability (X/Y/Z) (mm):

±0.004

Dimension(L*W*H):

2880*2350*2750mm

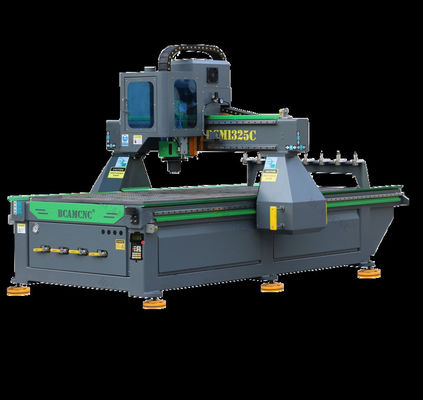

Model Number:

Vm1160

Voltage:

Customer's Requirement

CNC Control System:

FANUC

Toolpost Brand:

Hongda

Tool Post Stations:

8

Weight (KG):

4500

Warranty:

1.5 Years

Applicable Industries:

Machinery Repair Shops, Manufacturing Plant, Retail, Construction Works , Advertising Company, Other

Key Selling Points:

Automatic

Showroom Location:

Viet Nam, Mexico, Russia, Kazakhstan, Ukraine, Kyrgyzstan, Uzbekistan

Marketing Type:

Hot Product 2022

Machinery Test Report:

Provided

Video Outgoing-inspection:

Provided

Warranty Of Core Components:

2 Years

Core Components:

Bearing, Motor, Pump, Gear, PLC, Gearbox, Other

Working Desk Size:

1200x600

X/Y/Z Axis Travel:

1100/600/600

Distance From Spindle End To Worktable:

120-720

Distance From Spindle Center To Column:

650

Workbench T-slot:

5-18x100

X/Y/Z Axis Rapid Feed:

36/36/36

X/Y/Z Rail Specifications:

RGH45/45/45 P Grade

Taper Of Spindle End:

BT40-150

Minimum Positioning Unit:

±0.001

Disc Manipulator Tool Magazine:

24T

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!